Few of us think about how a better nozzle could reduce the entire spray can industry’s environmental impact. Yet at Bethel’s family-owned Ultramotive Corporation, that’s just what happened. Its patented EarthSafe Air Power System has the potential to eliminate tons of harmful hydrocarbons entering the atmosphere every year.

Few of us think about how a better nozzle could reduce the entire spray can industry’s environmental impact. Yet at Bethel’s family-owned Ultramotive Corporation, that’s just what happened. Its patented EarthSafe Air Power System has the potential to eliminate tons of harmful hydrocarbons entering the atmosphere every year.

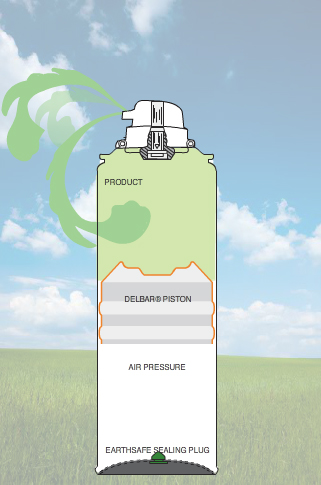

The company specializes in barrier packaging. In this case the breakthrough design is in the airtight seal between the viscous product (think shave gels and food products) in the can and the outside world. It uses fewer moving parts, meaning increased reliability and less raw material. It eliminates product waste by ensuring all of the can’s content gets out and it operates using lower pressure.

This last point adds another bonus. The lower pressure means the steel cans can have thinner walls, lowering the weight and saving tons of steel in the manufacturing process. Companies can see significant energy savings by increasing the number of tins on each pallet for transportation and reducing the number of vehicles needed to deliver the annual volume of metal containers.

Ultramotive Corporation is proud”, says Neil Putnam, Vice President of Sales & Marketing “to be associated with all the eco-friendly Vermont companies that support the goal of protecting our world’s environment.

Ultramotive estimates that if EarthSafe were used in just the 300 million cans of shave gel produced in the U.S. each year, it would prevent 2000 tons of hydrocarbons from being released.